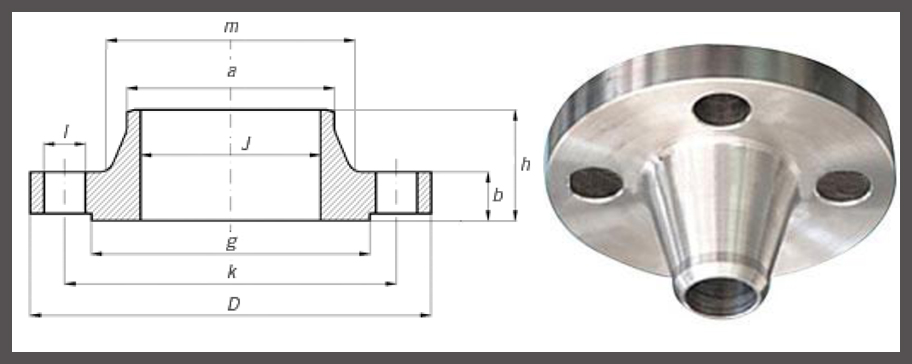

ANSI/ASME/ASA B16.5 Flange Weld Neck-RF

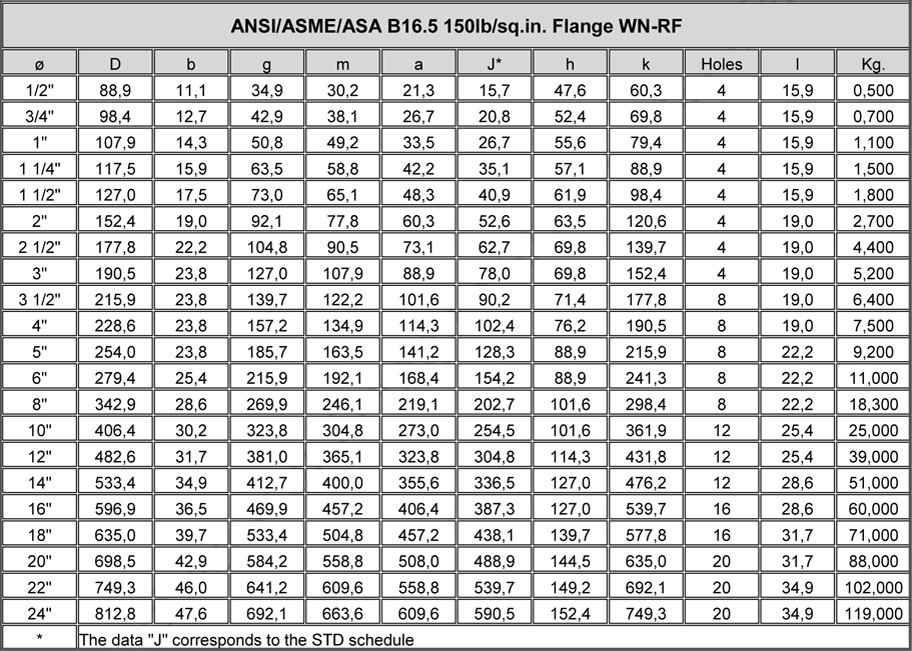

NOTE:

- Class 150 flanges except Lap Joint will be furnished with 0.06 (1.6mm) raised face, which is included in ‘Thickness’ (C) and ‘Length through Hub’ (Y1), (Y3).

- For Slip-on, Threaded, Socket Welding and Lap Joint Flanges, the hubs can be shaped either vertical from base to top or tapered within the limits of 7 degrees.

- Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.

- The gasket surface and backside (bearing surface for bolting) are made parallel within 1 degree. To accomplish parallelism, spot facing is carried out according to MSS SP-9, without reducing thickness (C).

- Depth of Socket (D) is covered by ANSI B 16.5 only in sizes through 3 inch, over 3 inch is at the manufacturer’s option.

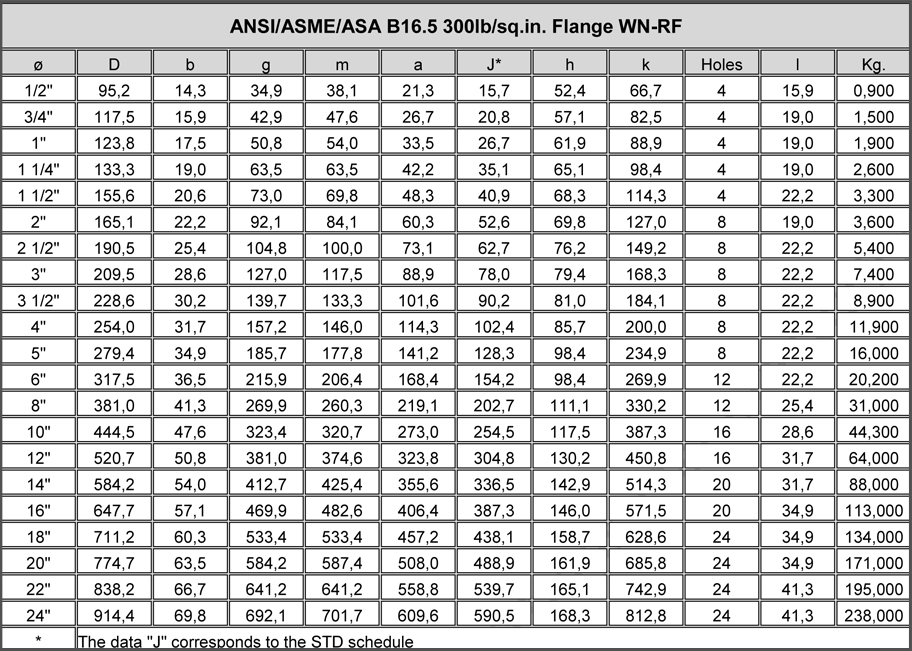

NOTE:

- Class 150 flanges except Lap Joint will be furnished with 0.06 (1.6mm) raised face, which is included in ‘Thickness’ (C) and ‘Length through Hub’ (Y1), (Y3).

- For Slip-on, Threaded, Socket Welding and Lap Joint Flanges, the hubs can be shaped either vertical from base to top or tapered within the limits of 7 degrees.

- Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.

- The gasket surface and backside (bearing surface for bolting) are made parallel within 1 degree. To accomplish parallelism, spot facing is carried out according to MSS SP-9, without reducing thickness (C).

- Depth of Socket (D) is covered by ANSI B 16.5 only in sizes through 3 inch, over 3 inch is at the manufacturer’s option.

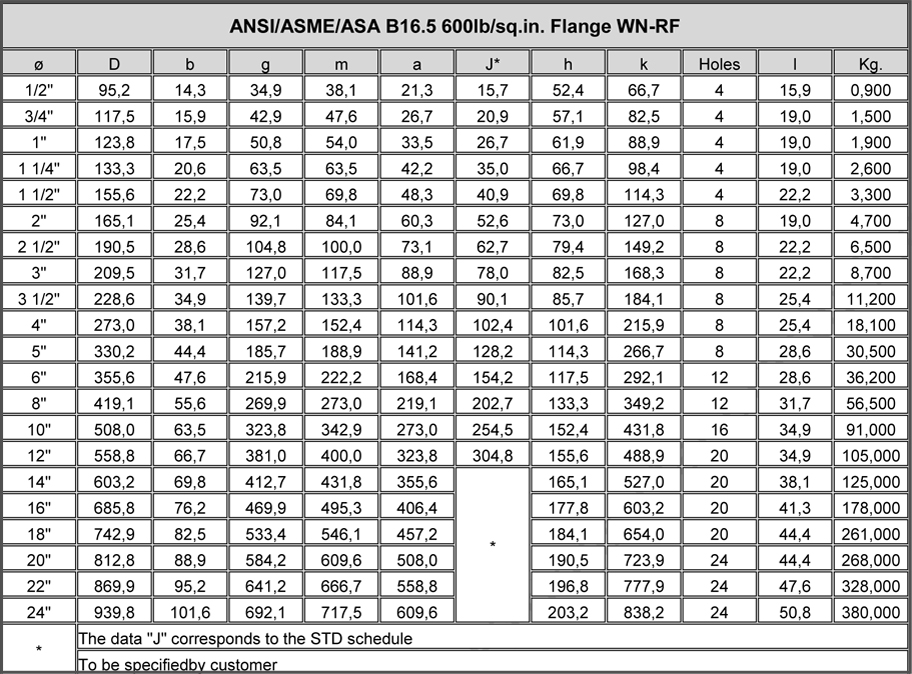

NOTE:

- Class 600 flanges except Lap Joint will be furnished with 0.25 (6.35mm) raised face, which is not included in ‘Thickness’ (C) and ‘Length through Hub’ (Y1), (Y3).

- For Slip-on, Threaded, Socket Welding and Lap Joint Flanges, the hubs can be shaped either vertical from base to top or tapered within the limits of 7 degrees.

- Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.

- The gasket surface and backside (bearing surface for bolting) are made parallel within 1 degree. To accomplish parallelism, spot facing is carried out according to MSS SP-9, without reducing thickness (C).

- Dimensions of sizes 1/2 through 3 1/2 are the same as for Class 400 Flanges.

- Depth of Socket (D) is covered by ANSI B 16.5 only in sizes through 3 inch, over 3 inch is at the manufacturer’s option